Photolithography Module

AB-M Aligner #1 (UV)/ (DUV) and #2 (UV)

Light-source illumination: DUV/UV wavelength selectable (500 W Mercury DUV lamp)

Alignment printing mode: Manual

Soft contact: Contact vacuum adjustable

Hard contact: Full vacuum contact

Photomasks: 5" square or 7" square

Substrate sizes: > 5 mm2 to 4" square, or 6"

Special feature: Backside alignment using infrared

No. of machines installed: 2

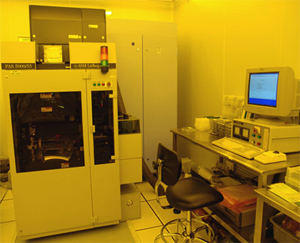

ASML Stepper (ASML PAS5000/55 Stepper)

Light-source illumination: i-line (365 nm)

Resolution: 0.5 µm

Overlay alignment accuracy: ± 0.1µm (3 σ)

Wafer sizes: 4" or 6"

Field sizes: 15 mm × 15 mm or 10 mm × 10 mm (on wafer)

Reduction ratio: 5:1

Photomask size: 5" square

Karl Suss Bonder SB6

Anodic bonding and silicon fusion pre-bonding

Wafer size: 4”

Substrate materials: Silicon or Pyrex Glass

Pressure: 5×10-5 mbar to 2 bars

Karl Suss MA6 #1 and #2

Light-source illumination: i-line (365 nm)

Resolution: 1 µm

Substrate sizes: > 5 mm2 to 2" or 4"

Photomask size: 5” square

Exposure modes: Contact (soft, hard, low vacuum and Vacuum)

Proximity (exposure gap 1-300 µm); Flood Exposures

Alignment methods: Top-Side Alignment (TSA); Bottom-Side Alignment (BSA)

Alignment accuracy: TSA (down to 0.5 µm); BSA (down to 1 µm)

No. of machines installed: 2

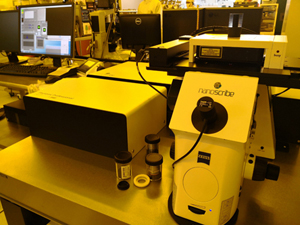

Nanoscribe 3-D Printer

Resolution (depends on the objective lens and the resist):

- 3-D lateral feature size: ≤ 200 nm

- 2-D lateral resolution: ≤ 500 nm;

- Vertical resolution: ≤ 1,500 nm

Speed:

- Beam-scanning speed: 10 mm/s

- Piezo-scanning speed: 100 µm/s

Range:

- Motorized xy-scanning stage range: 100 × 100 mm²

- x-y-z piezo range: 300 x 300 x 300 µm³

- x-y galvo-scan range: 200 - 600 µm Ø depends on scanning objective

Height:

- Object height fine: ≤ 300 µm

- Object height coarse: 3 mm

Objective:

- Immersion Objective: 63×, NA = 1.4; WD = 190 µm

- Immersion Objective: 25×; NA = 0.8; WD = 380 µm

- Air Objective: 20×, NA = 0.5; WD = 2.1 mm

Sample holders:

| Model | Substrate Type | Substrate Dimensions | Substrate Thickness |

| DiLL | DiLL substrate | 25 mm × 25 mm | 0.7 mm |

| Microscope slide | 24 – 26 mm × 50 – 76 mm | 1.0 mm | |

| Cover slip | Ø 30 mm | 0.17 mm | |

| Cover slip | Ø 25.4 mm | 0.3 mm | |

| 2" wafer | wafer | Ø 2" | 0.35 - 0.55 mm |

| 4" wafer | wafer | Ø 4" | 0.35 - 0.55 mm |

| 10 × Ø 30 mm | Cover slip | Ø 30 mm / 22 mm × 22 mm | 0.17 mm |

Printing configuration:

| Configuration | Objective | Immersion medium | Substrate(s) | Resist |

| Oil immersion | 63× NA 1.4 | oil | glass 170 µm | IP-L 780 |

| Air | 20× NA 0.5 | air | Silicon, glass | AZ resist, SU8 |

| DiLL | 25× NA 0.8 | ITO-coated glass, Silicon | IP-S | |

| 63× NA 1.4 | fused silica | IP-DIP |

CEE Coater

Spin-speed range: 0- 6,000 rpm

Spin-speed acceleration: 0-30,000 rpm/s

Substrate sizes: 4" or 6"

Others: Frontside-edge bead remover

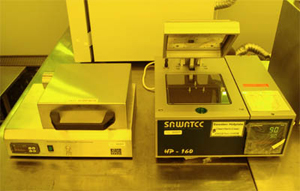

Desktop Coater

Spin-speed range: 0 to 5,000 rpm

Substrate sizes: > 5 mm2 to 4" square

EVG Spray Coater

Speed range: up to 10,000 rpm

Ramp-up speed: 0-40,000 rpm/s

Heat-chuck temperature: up to 70 ± 1 oC

Spray speed integrate with heat chuck: < 1,500 rpm

Spray-coating nozzle: Ultrasonic Atomizer Nozzle

Syringe dispense rate: 0.01 ml/s to 5 ml/s

Substrate sizes: up to 200 mm or 150 mm × 150 mm

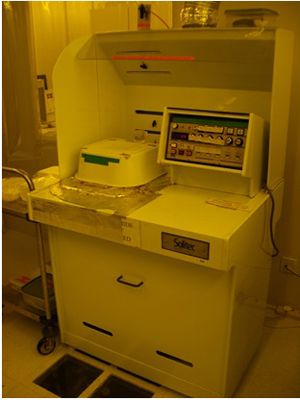

Solitec Coater #1

Spin-speed range: 250 – 5000 rpm

Spin-speed acceleration: 1000 – 4000 rpm/sec

Substrate sizes: Larger than 5 mm, 2 to 4", 5" square for single-side coating or 4" for double-side coating

SUSS Coater

Spin-speed range : 0 to 7000 rpm

Spin-speed acceleration: 0 – 5000 rpm/s

Coat system: Open Bowl; GYRSET

Substrate sizes: > 5 mm2 to 6" or 5" square for single-side coating, 4" for double-side coating

Others: Programmable bowl auto-clean; Edge-bead remover

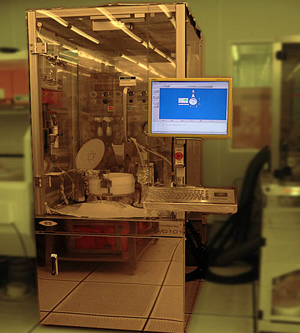

SVG88 Coater Track and SVG88 Developer Track

Automatic tracks for resist coating and developing

No. of tracks: 2

Coat track feature: Vapor prime chill plate; Coat module backside rinse; Frontside edge-bead remover; two hot plate ovens

Develop track: Developer module, chill plate, two hot plate ovens

Coating uniformity: ± 0.3 %

Wafer size: 4" and 6"

Wafer loading/unloading: Cassette-to-cassette

High-Temperature Conventional Oven

High-temperature oven: Up to 450 oC

Conventional oven temperature: Up to 250 oC

Substrate sizes: Up to 6"

Hot Plates

Computer temperature-controller with digital readout

Substrate sizes: up to 6"

Temperature: 50 to 250 oC

Temperature uniformity: ± 1 oC

Vacuum Oven

Temperature: Up to 300 oC

Substrate sizes: 1 cm2 to 4"

Vacuum: 0 to 30 in.Hg

Others: N2 purge

Nikon IC Inspection Microscope with a Digital Camera

Contrast methods: BF /DF/ DIC/ Fluorescence

Magnification: 50× - 1500×

Wafer holder: up to 6"

Mask holder: 5" square

Digital camera: 5M-pixel CCD

Display: 8.4" TFT LCD XGA

Software: Dimension measurement tool