Thermal Diffusion and Ion-Implantation Module

310PC PECVD (STS 310PC PECVD)

Processing:

- Silicon dioxide

- Silicon nitride

- Silicon oxynitride

- Amorphous silicon

CNT PECVD (SEKI AX5200 Microwave CNT PECVD)

Frequency: 2455 MHz

Processing: CNT growth

Temperature: 900 oC

ET3000 Epitaxy (FirstNano ET3000 Epitaxy Reactor)

- Epitaxial layers of silicon, silicon germanium, N-doped (PH3), P-doped (B2H6)

- Fit for up to 4" wafers

LPCVD

Each deposition has its programmed flow of gas compositions, temperature and pressure

ASM LB45 LPCVD Furnace:

Polysilicon, amorphous silicon, N-doped amorphous silicon, silicon germanium, silicon nitride,

low-temperature oxide (LTO), phosphorous silicon glass (PSG)

Flokal LPCVD Furnace:

Polysilicon, amorphous silicon, silicon nitride,

low-stress silicon nitride, LTO, PSG

Oxford ALD (Oxford OpAL Plasma ALD)

Thermal and plasma ALD

Processing:

- Aluminum oxide (Al2O3)

- Zirconium oxide (ZrO2)

STS PECVD (STS Multiplex PECVD)

Processing:

- Silicon dioxide

- Silicon nitride

- Silicon oxynitride

- Amorphous silicon

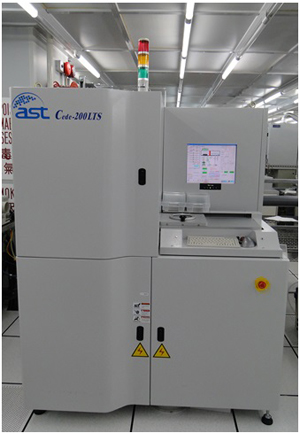

TEOS PECVD (AST Cede-200 TEOS PECVD)

Processing:

- TEOS Silicon dioxide

Diffusion Furnace (ASM Diffusion Furnace)

Operating temperature: 400 to 1150 oC

Processing:

- Dry & wet oxidation with TCE

- N/P diffusion

- Forming gas annealing and drive-in

AG610 RTP (Allwin21 AG610 RTP)

- Operating temperature in the range of 400 ℃ to 1000 ℃

- Ion-implantation annealing

- Silicide formation

- Nitridation of thin gates, dielectrics & silicide

- PSG/BPSG reflow

AW610 RTP (Allwin21 AW610 RTP)

Wafer handling: Manual loading of wafers into the oven, single-wafer processing

Wafer sizes: Small samples and 2", 4" and 6" wafers

Ramp-up rate: Programmable, 10 ℃ to 80 ℃ per second

Ramp-down rate: Programmable, 10 ℃ to 80 ℃ per second

Operating temperature in the range of 250 ℃ to 800 ℃

Ion-implantation annealing

Silicide formation, nitridation of thin gates, dielectrics & silicide, PSG/BPSG reflow

RTP-600S (MPT RTP-600S)

Steady-state temperature stability: ±2 ℃ in the range of 250 – 1150 ℃

Heating rate: 0 – 200 ℃/sec

Cooling rate: 150 ℃ max. /sec

Steady-state time: 1 – 600 sec

CF-3000 Implanter (Varian CF-3000 Ion Implanter)

Dose Energy: 10 to 180 keV

Max. Dose (ion/cm2): 1016

Processing:

- Arsenic

- Phosphorus

- Boron

- BF2

- Hydrogen implant