Sections

Text Area

Wet Etching and CMP Module

Wet Station

Left Column

Image

Image

Right Column

Text Area

Wet Stations A, B, C, D, E, F, G and H

Wet processing:

- Silicon Etch using KOH / TMAH (25%)

- Photoresist Strip / ITO Etch

- Aluminum Etch / Pad Oxide Etch

- Oxide / Nitride Etch

- Wafer Cleaning (RCA)

- Wafer Cleaning (Piranha Clean)

- Solvent Cleaning

Text Area

Left Column

Image

Image

Right Column

Text Area

Wet Station M

- MS2001 resist stripper

- FHD5 manual developer

- Quick dump rinsers

- Small samples of sizes of up to 6"

Text Area

Left Column

Image

Image

Right Column

Text Area

Wet Station O

- Hydrochloric acid etch prior to E-Beam metallization

- DI water gun for rinsing

- N2 gun for drying

- Small samples of sizes of up to 6"

Text Area

Left Column

Image

Image

Right Column

Text Area

Wet Stations W, X, Y and Z

- MS2001 resist stripper

- FHD5 manual developer

- Quick dump rinsers

- Small samples of sizes of up to 6"

Text Area

Text Area

CMP

Left Column

Image

Image

Right Column

Text Area

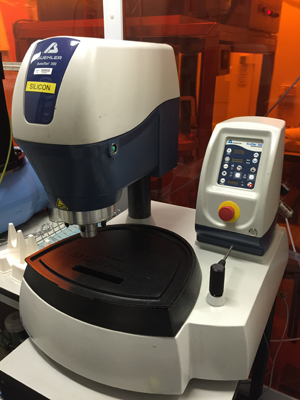

Buehler Polisher #1

- Polished for silicon, silicon oxide or silicon nitride

- > 5 mm2 to 4" wafer size

- 100 - 800 µm wafer thickness

Text Area

Left Column

Image

Image

Right Column

Text Area

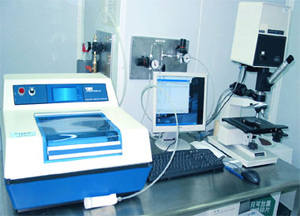

Buehler Polisher #2

- Polished for copper, CNT, silicon, silicon oxide or silicon nitride

- > 5 mm2 to 4" wafer size

- 100 - 800 µm wafer thickness

Text Area

Left Column

Image

Image

Right Column

Text Area

Silicon Grinder

- Mechanical grind for silicon oxide or silicon using a diamond wheel

- > 5 mm2 to 4" wafer size

- 100 - 800 µm wafer thickness

Text Area

Left Column

Image

Image

Right Column

Text Area

Strasbaugh CMP

- Polished for silicon dioxide or polysilicon

- 4" wafer size

- 400 - 550 µm wafer thickness

- Touch-screen graphical user interface

- Hydrolift loading station

Text Area

Left Column

Image

Image

Right Column

Text Area

USI Wafer Cleaner

- Wafer surface scrubbing for pre-CMP and post -CMP process

- Fully automatic microprocessor control

- Completely enclosed chamber for washing, rinsing and drying

- 4" wafer cleaning

- 9" brush travel

Text Area

Text Area

Electroplating

Left Column

Image

Image

Right Column

Text Area

Copper Electroplating

- Copper electroplating on 2" single-side or 4" single/double-side wafer size

- Ready for copper electroplating to fill small trenches with 300 - 550 µm wafer thickness